Mechanics Engineering Services

Introduction

It is our great pleasure for availing chance of introducing our company which is known in the business sphere as "MECHANICS" Engineering Services. We have gained reputation in the market by dint of standard and specific services and supplies relating to Power and Generators Sets (Gas/Diesel) to our worthy Clients during the last 15 years. Our company was formerly known as "PROGRESSIVE ENGINEERING COMPANY".

Our company is a sign of 'Standard working' side by side fulfilling the satisfaction of our worthy clients with our services.

Briefly stated that our company is attaining business in regard to:

Consultancy in regard to the above working/services/supplies is given to the clients for better set up.

Vision

Be the market leader in everything we do Empower employees Develop first class facilities , equipment & tooling Exceed customer needs & expectations Create a culture of customer service , quickly respond to customer complaints

MISSION

Our mission is to achieve highest level of working and widen the form of facilities to our clients. Maintain our motto of satisfaction of Clients in our dealing and with most suitable manner of servicing. On account of this principle we are very successful in strengthening our business relations with the clients and also it proved faithful in attracting our new clients.

Purpose Statement

To bring prosperity and well-being to our stake holders and society at large by adding value through engineering, technology and management.

Core Values

Mechanics Engineering Services aims to install a fostering and stimulating culture based on providing a safe, healthy and supportive environment where staff members are valued, respected and able to realize their full potential. This culture is based on the following core values:

- Extreme Customer Care/Focus

- Courtesy and Respect

- Honesty, Integrity and Trust

- Commitment and Hard work

- Creativity, Innovation and Quality

- Justice and Fairness to all Stake-Holders

- Open, Honest and Direct Communication

- Provider of growth and equal opportunity

Objectives

To grow further as a commercially viable integrated engineering company having a reputation for delivering projects & products of international quality, within scheduled time & in a safe manner.

To develop a cadre of highly dedicated and professional employees in all fields of company business and its related support functions through an effective Human Resource Development Program.

To perpetually strive towards persistent improvement in the operating efficiency in all areas through productivity improvement techniques & work measurement norms.

To induct effective management, technology & know-how through active participation of employees & interaction with outside agencies.

Engineering

Spray Drying Unit

Mechanics engineering is capable to execute Turnkey Projects in dairy industry, textile, leather, Chemical industry. we are well equipped with appropriate knowledge and man power to build a variety of plants for the above mentioned industries. all systems comply with sanitary standards and are capable of being cleaned in place.

Engineering

Conventional Two-Stage Spray Dryer

Powder discharged from the drying chamber can be further dried and cooled in a vibrating fluid bed, the PDL Niro Vibro Fludizer. This two stage drying concept achieves better overall heat economy and is suitable for many food and dairy products. When non-agglomerated powders of non-fat products are dried, a pneumatic transport system can replace the fluid bed.

Engineering

Compact Spray Dryer

Atomization is created by either a rotary atomizer or spray nozzle atomizer. The location of the fluid bed within the drying chamber permits drying to be achieved at lower temperature levels resulting in higher thermal efficiencies and cooler conditions for powder handling. The plant can be equipped with pneumatic transport system for many powders or with an external vibrating fluid bed for agglomerated powders.

Engineering

Tanks & Vessels

Mechanics Engineering Manufactures A Variety Of Process Equipment Such As Storage Tank. Ss Silo, Heat Exchanger, Reactor, Mobile Tanker, Dumb Tank, Oil Storage Tank, Centrifuges, Spray Dryers And Filter Press.

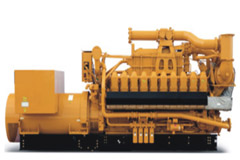

Generators

Assembling And Installation

- Local Assembling And Installation Of

- Automatic Synchronizing & Paralleling Of Multi

- Genset Industrial Marine Electrical Installation

- Electrical And Electronic Control System

- Avr: Automatic Voltage Regulator

- Pfp: Power Factor Improvement

- Amf/ats Panel:

- Sound & Weather Proof Canopy

Generators

Fabrication & Erection

- Gas & Oil Line

- Chemical Plants

- Dig & Pumping Station

- Air Vessels & Bulk Storage Tanks

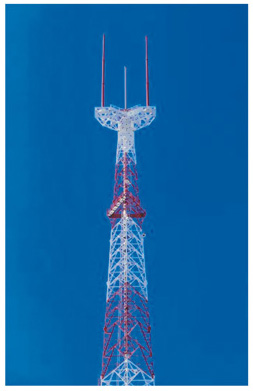

- Communication / Transmission Towers

Generators

Sale Services & Rental

- Advisory For Generator Sets

- Diesel / Gas / Furnace Oil / Steam

- Slow Rpm / High Speed 10 Kva - 2000 Kva

- Power Plants 1 Mw - 500 Mw

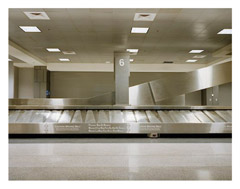

CONVEYORS

- Floor Conveyor

- Trolley Conveyor

- Hinged Steel Belt Conveyor

- Rubber Belt Conveyor

- Monorail Conveyor

- Conveyors for Growers

- Enclosed Track Conveyors

- Recycling Conveyors

CRANES

- Bridge Crane

- JIB Crane

GAS & WATER BOWSERS

We can provide a range for water bowsers for the job of water supply at anywhere. We manufacture towable water bowers have either a 500 litre or 1100 litre capacity and with the addition of a petrol pressure washer the bowser becomes a fully mobile cleaning unit. Our Bunded Fuel Bowsers use a unique patented design to totally eliminate the risk of contamination to the environment by spillages.

Telecommunication and Transmission Lines

Porta Cabins

PORTA/ SHIPPING CABINS

Mechanics Engineering Manufactures a variety of Porta and Shipping Cabins in different sizes & style which uses for:

- Hall Office

- Hall Office with Bath

- Bed room with attach bath

- Hall with Kitchen

- Mess Hall

- Store Hall

- Mosque Hall

- Ablution Block

- Bed room with Bath and Kitchen etc

Porta/ Shipping cabins are made of MS Structure and finished with wooden pilling, Vinyl Flooring, Electrification, Windows and Doors, Bath Fittings, Insulation with Thermo pore/ PU, AC windows/Split (Provision), Kitchen accessories (Provision).

Available Sizes (PORTA CABINS)

- 10 x 20 ft

- 10 x 30 ft

- 10 x 40 ft

Available Sizes (SHIPPING CABINS)

- 8 x 20 ft

- 8 x 40 ft

Hot Dip Galvanizing

Hot Dip Galvanizing dates back to 1800s for the protection of steel. It is the process of applying a zinc coating to fabricated iron or steel material by immersing the material in a bath consisting primarily of molten zinc. Galvanizing is considered a factory controlled metallurgical combination of zinc and steel that provides corrosion protection in a wide variety of environments. It also provides cathode protection where the zinc sacrifices itself to protect the base steel. Galvanizing has had a proven history of industrial success as a method of corrosion protection in countless applications. It can be found in almost every industry where steel is used.

Hot Dip Galvanizing

Galvanized coating can be fully re-cycled which makes it very environmental friendly. Zinc (our major raw material) is an efficient and sustainable material that reinforces economic growth whilst protecting the environment. In this step the material is completely immersed in a bath consisting of minimum 98.5 percent pure molten zinc. The bath chemistry is specified by the ASTM A123 / British Standard 729 / BSEN ISO 1461. The bath temperature is maintained at approximately 450 to 460 degrees calcies. Fabricated items are immersed in the bath long enough to reach bath temperature. The articles are slowly withdrawn from the galvanizing bath, and the excess zinc is removed by draining and vibrating. The chemical reactions that result in the formation and structure of the galvanizing coating continue after the articles are withdrawn from the bath as long as these articles are near bath temperatures. The articles are cooled in either water or cols air immediately after with drawl from the bath.

Working Partners

Contact

Office

308-West Canal, Bank Road, Lahore

Ph: +92 42 3529 29 06-8, Fax: +92 42 3529 29 05

Works Unit I

4-Industrial Estate, Gulshan Ravi, Bund Road, Lahore

Ph: +92 42 3740 48 03-4, Fax: +92 4237404805

Works Unit II

28-KM, Ferozepur Road, Lahore

Email: info@mechanics.com.pk

Bangladesh Office

Shuvastu Villa House No 114, Road No 15, Block-C, Banai, Dhaka 1213, Bangladesh.

Ph: + 880-2-8812310. 8827 66, Fax: + 880-2-8812 310

- Welcome

- About us

- Our mission

- Services

- Contact us

- use the arrow keys to move the slides